Smart technology and AI: the engine for productive processes

Organizations today face a dual challenge: ever-increasing customer expectations while at the same time increasing pressure on costs and staff. The answer to that challenge lies in working smarter, not harder. And precisely at that intersection, we bring together Lean Management and Six Sigma with AI.

Lean Six Sigma as a foundation

Lean Management is all about eliminating waste: unnecessary steps, wait times or duplication of effort that cost energy and add no value.

Six Sigma adds data-driven quality improvement: reducing variation, reducing errors and making processes predictable.

Together, Lean and Six Sigma have been a powerful foundation for productivity improvement for years.

They help organizations simplify processes, speed them up and make them more reliable.

But… more is possible.

“I need to do something with AI, but what?”

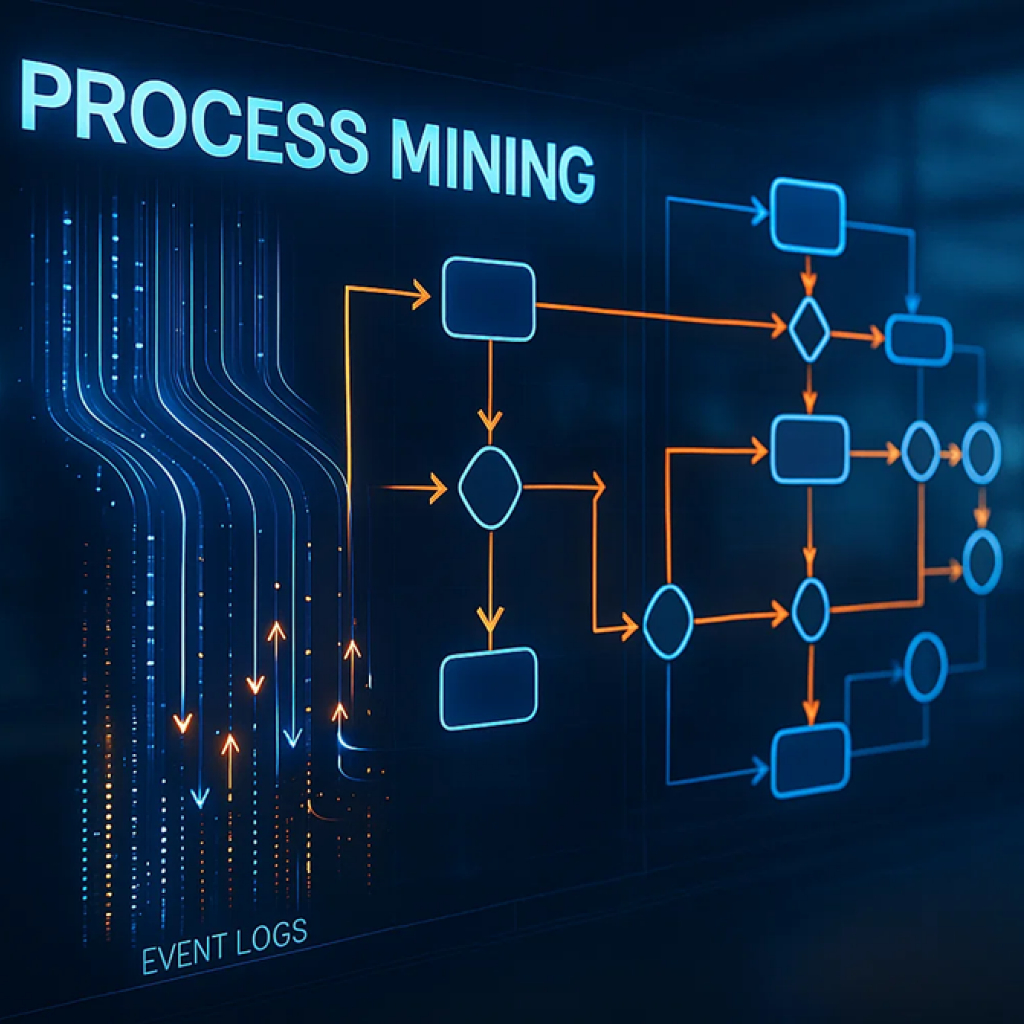

Traditionally, analyzing processes takes a lot of time. Workshops, interviews and measurements are valuable, but don’t always show the full picture. AI and smart technology dramatically accelerate this process, revealing patterns that humans alone cannot detect. Organizations looking to increase productivity often turn to proven Lean methods such as Value Stream Mapping (VSM). At the same time, a relatively new approach is rapidly gaining ground: Process Mining.

At first glance, they seem to do the same thing: make processes visible. But a closer look reveals that they are two very different approaches that complement each other perfectly.

Process Mining

With Process Mining, digital traces in systems are translated into a visual overview of how processes really work. You see immediately:

- Where delays and bottlenecks occur

- Which steps are duplicated

- Where errors or exceptions occur most often

In Lean terms, you get an X-ray of the waste in your organization. Where Six Sigma normally takes weeks of analysis, Process Mining reveals patterns and bottlenecks in a matter of hours.

Machine Vision: seeing and learning smarter

Machine vision literally means: a machine that can “see.”

These are systems that process and understand images or video. Think of cameras that scan products, recognize faces or detect anomalies in a production process.

Without AI, machine vision can mainly recognize patterns or count things (e.g., “is this product present/not present?”).

With AI (and especially deep learning), it goes much further:

- The system itself learns to distinguish between complex objects.

- It can recognize variations (e.g., a scratch, stain or wrong size).

- It improves itself through training with new data.

In manufacturing, healthcare and logistics environments, Machine Vision combined with AI makes it possible to not only watch, but also learn. Regardless of quantities, Production Parts can be automatically checked for deviations. Sampling is thus made obsolete. All documents and invoices in an organization are recognized, processed and stored without error. But perhaps one of the most important benefits: employees receive support for repetitive and error-prone tasks. This ensures a lower error rate and a boost in job satisfaction.

The result? Higher quality, less repair work, more time for valuable work.

AI + Lean = scalable Kaizen

Lean teaches us that small improvements (Kaizen) make a difference every day. Traditionally, this comes primarily from employee observation and experience. With AI, this principle becomes scalable because technology is constantly watching and recognizing patterns that people don’t always see.

If a process normally takes 2 days, but sometimes takes 7 days, the system recognizes that pattern and marks it as waste. AI systems thus automatically identify deviations or waste. This gives employees suggestions for improvements based on data and allows for faster and more informed decisions.

It’s the power of Lean and Six Sigma, but enhanced by technology that thinks along 24/7. It breathes continuous improvement!

Lean and Six Sigma have always been about getting better one step at a time. What AI adds is speed and scale. When you know how to integrate AI into your continuous improvement culture, you as an organization will not only be able to keep up, but more importantly, be ahead.

Therefore, keep this in mind:

- Continuous improvement no longer becomes a separate project, but a daily routine supported by data.

- Productivity increases structurally because errors and waste are immediately visible and solvable.

- Innovation is given room because employees spend less time putting out fires.

Event: AI and Productivity

At Symbol, continuous improvement is in our DNA. For years, we’ve helped organizations use Lean and Six Sigma to make processes smarter and more productive. Now we are adding to that the power of AI. Precisely this combination makes it possible to not only conceive improvements, but also to make them immediately visible, scalable and sustainable. During the AI & Productivity event we share this knowledge and let participants experience how smart technology and proven methodologies together ensure structural productivity growth. During the event we bring these worlds together.

- Learn how Lean and Six Sigma lay the foundation for process improvement

- Discover how AI, Process Mining and Machine Vision are accelerating and deepening this

- Get inspired by experts and partners with proven tools and applications

- Participate in various workshops and network with industry peers.

- Go home with concrete ideas that you can deploy in your organization as early as tomorrow

Sign up today for the AI & Productivity event on Nov. 26, 2025 and experience how technology and Lean together make a difference.

Also interesting to read

Quality by Design

Event Quality by Design - Engineering Excellence under Margin PressureLanguage: EnglishImproving quality while margins are under pressure is a daily challenge for many manufacturing companies. Customers increasingly demand customization and variety, while demands for...

Klarna saved 40 million with AI but lost the trust of its customers

Klarna saved40million with AI but lost the trust of its customersThe question sounds absurd: how do you eat an elephant? But the answer is surprisingly simple and powerful: one step at a time. This metaphor is often used to describe how to tackle large, overwhelming...

How do you eat an elephant?

Dutch productivity is falling again - and that offers precisely opportunitiesLabor productivity in the Netherlands fell again in 2024, CBS figures show. While the economy is growing, the output per hour worked is actually decreasing. A signal that traditional ways of...