30% shorter lead time and new products on the way: MOSO grows thanks to Symbol

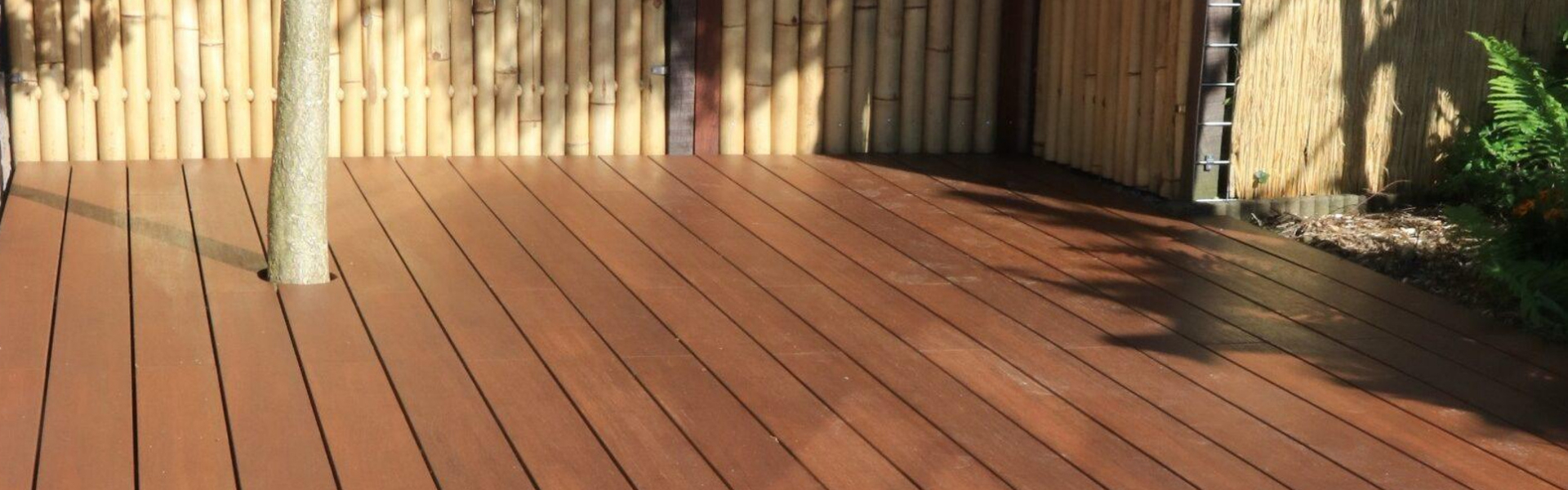

MOSO develops bamboo products for indoor and outdoor use, such as flooring, cladding and urban furniture. All products meet the highest technical requirements as well as European and American quality standards. CEO Norman Willemsen: “Bamboo meets the need for an environmentally friendly solution – the CO₂ absorption is enormous. And because bamboo is engineered, it has unprecedented design possibilities. MOSO has been operating for 30 years in now more than 60 countries. That makes us a strong global player – market leader even. I have been with MOSO since March 2024, with the ambition of working with our team to usher in the next phase of sustainable growth. A phase in which innovation, scalability and social impact are central.”

Working (together) smarter and more efficiently

“When I started in March 2024, I took a fresh look at the organization: where are we, where do we want to go and what do we need to get there?” continues Norman. “What struck me immediately was the tremendous passion and commitment of our people. Entrepreneurship and creativity are in MOSO’s DNA. That’s a strength you want to nurture and strengthen. At the same time, we saw opportunities to improve our processes. Not to change people, but to support their work smarter. To collaborate better, switch faster and serve our customers even more consistently. That’s why we chose Symbol. And we specifically chose Peter Bos because of his keen insight and ability to get people moving.

Listening, watching and choosing

Peter: “I engaged with employees throughout the organization, in the Netherlands and abroad. I also observed what was happening in practice. On the basis of my experience, I then made an assessment: where should we start and where can we achieve real impact with limited effort? Together with the management it was then decided to start with the R&D department. This department was clearly overloaded and therefore a bottleneck when it came to lead times and response times. An additional advantage: if this department were to function better, other departments – such as sales – would also benefit directly.”

“Our people haven’t changed, our methods have. And that makes all the difference.”

Many initiatives, little prioritization

In the R&D department, Peter brought structure to a situation that Norman describes as a place with lots of energy and ideas but little prioritization. Peter: “Here I placed much more responsibility with the employees in order to relieve the manager. Improvement teams were created that I trained on the job. There was also a challenge in terms of content. All applications were lumped together and handled in the same way. We adjusted that process: the team now prioritizes based on complexity, urgency and risk. Complex or high-risk requests now receive personal attention; simple requests are automated. So: speed where we can, attention where we have to.”

Working smarter with tools and ownership

Peter continues: “I also created an overview: what are we all working on, for how long and who is doing what? For this work in progress I introduced several applications. One of the employees turned out to have a great affinity with software and enjoyed setting up this tooling. The input from sales, the internal customer, was also crucial here: what exactly do you want, what must it meet? By putting this into the system properly, requests are now processed correctly and faster. This sometimes means some extra work in the preliminary stages – something that initially met with resistance from sales. But ultimately it saves a lot of time and endless back-and-forth mail.”

Restart of product development

Norman: “Because we now work better and smarter, there is also room again for New Product Development. We can now turn our core competencies – entrepreneurship, creativity and quality – into solutions for concrete customer needs, for example with architects and large builders.” Peter: “In the new process for New Product Development, ideas are assessed on a project basis and – if they are promising – taken up. This is done in small multidisciplinary teams, always led by a project leader from the R&D department. This involves clear planning: who does what and when? This allows MOSO to launch new products in a predictable way. So much time has been saved from reactive work that there is now structural space for innovation. There are several promising products in the pipeline to be launched in the near future.”

Better insight, fewer claims

Peter additionally took up the subject of claims and complaints. Norman: “Of course you want to prevent them. But if they do happen, we want to learn from them and make sure they don’t happen again. However, we did not have a system for registration and prevention – now we do. This has given us more insight into our claims and enabled us to develop preventive methods. And that works: we now see a decrease in the number of claims.”

Small steps, concrete results

Peter also sees great results: “People themselves take the responsibility and initiative to organize processes smarter and improve them together. There are also hard results. For example, the processing time of applications has been reduced by 30%. Taking small steps, but continuously: that is the success factor.” What else is in the pipeline? Norman: “As an SME you have to find the balance in improvement projects between what it costs and what it delivers. We are now looking at which department we can add the most value with the next improvement project. But one thing is certain: our next step we will take again together with Symbol and Peter.”

%

reduction in lead time

Looking for inspiration and improvement?

Want to learn more about Symbol’s project approach? Then contact us at 053 – 20 30 240 or using the form below. Getting started with process improvement yourself? Then check out our Lean Green Belt and Lean Black Belt training courses!