Mitsubishi Turbocharger and Engine Europe (MTEE): achieving win-win situations with audits

The automotive industry has been reeling for years, and OEMs will continue to face significant challenges in the coming years. Emissions must continue to come down, for example, and trends such as autonomous driving and mobility as a service are becoming more visible. And this is just the tip of the iceberg. It is now more important than ever to have a fit chain that knows how to adapt well to these challenges to maintain quality and reliability.

“An audit is not a piece of wood you can beat suppliers with.”

Benefits of good auditing

Good auditing won’t hurt you in the process. Whether they are standard audits – testing for a change or a problem – or audits designed to support and drive supplier development. Fewer complaints in the chain, higher efficiency, better cooperation with suppliers, faster response to any problems in the chain, better response to changes in the automotive industry: the benefits are easy to list.

Effective testing

Symbol trains OEMs and their suppliers in how to perform those audits to the best of their ability. During the trainings, participants increase their knowledge, but most importantly, they gain practical skills that they can use to conduct supplier audits. Such is the case with Mitsubishi Turbocharger and Engine Europe (MTEE). “Our Supplier Quality Development department is expected to be able to test suppliers against the standards that are out there, including IATF16949. That means that not only do we have to know the standard well, but we also have to be able to effectively test against that standard. For a number of people in our department, the latter was fairly new. That is why we asked Symbol – a reputable supplier that we have been using regularly for years – to provide a multi-day training course in order to bring our entire department up to the same level of knowledge,” says Paul Soetens, Manager Supplier Development at MTEE.

Increase competencies

Enhancing auditors’ competencies: that’s what Symbol’s trainings are all about. This starts with good preparation. An auditor has to know how to interpret the context of the supplier environment, has to take into account possible cultural differences AND has to know how to interpret the right info in the right way and let the auditing loose on that. And after the audit, of course, firm feedback to the supplier’s management is important so that attention is paid to it within the supplier’s organization.

Focus on skills – do’s and don’ts while auditing

This and more was also covered during the training at MTEE. Soetens: “Before the training we mapped out, together with Symbol, which persons were involved and what their level of knowledge was. Symbol adapted the training accordingly: the focus was mainly on acquiring skills (do’s and don’ts during auditing) and less on theory. What do you test for during an audit? How do you do that? And what do you do if a supplier does not want to cooperate, or presents things differently than they are? By means of role plays, the participants practiced with audit situations that often occur. They are now well prepared for them. Important, because audits are often surrounded by a strange atmosphere. In a good audit there is interaction between the auditor and the supplier. There is a common objective, namely: to improve processes. But many suppliers are not waiting to be tested on their performance. The trainer taught the participants to conduct audits in a motivating manner, and not to take a diametrically opposed stance towards the supplier. An audit is not a piece of wood you can hit suppliers with. If you do it right, it benefits both parties.”

Using motivational techniques to achieve win-win situations

Soetens then is very pleased with the training his colleagues have received. “This is because of the approach as I just described – using motivational techniques, in order to achieve win-win situations – but also because of the good balance between theory and practice. Standards can be quite boring, and because of the variety and interactivity, the trainer captivated the participants from start to finish. And now it’s time for the next step. I compare it to driving a car: only after you get your driver’s license do you really learn to drive well. The five participants have now all obtained their certificates and are certified auditors, but now they must put what they have learned into practice and gain experience. They are actually still in their infancy.”

‘Stronger in my shoes’

A number of participants have now completed their first audits. Soetens: “I notice that their knowledge of the standards has clearly improved. And I also notice that they have this win-win situation in their sights and continue to do so. I find that most important, because it ensures competent auditing and better cooperation with the supplier. Or as one of my colleagues who took the training told me: ‘I have learned how to convince suppliers that it is important for them too to enforce the rules. This makes me feel stronger. I also now know how to maintain a professional structure during an audit, which makes audits go more smoothly.’ That’s great to hear.”

Realize lasting impact with Symbol

Symbol is a specialist within the automotive industry. Want to know more about our Internal Auditing IATF16949: 2016 training or our other training courses for Automotive? Then click on the links or contact us! We can be reached by phone at 053-20 30 240 or ask your question using the form below!

Latest news/blogs

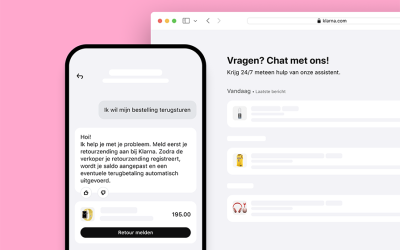

Klarna saved 40 million with AI but lost the trust of its customers

Klarna saved40million with AI but lost the trust of its customersThe question...

How do you eat an elephant?

Dutch productivity is falling again - and that offers precisely opportunitiesLabor...

From Theory to Practice: Junior Consultant at Stoneridge

From theory to practice: Junior Consultant at Stoneridge Before working at Symbol,...