Product Lifecycle Management

PLM was initiated by the American Motors Corporation (AMC) in 1985. The automaker was looking for a way to accelerate its competitiveness through innovation and shorten needed time-to-market. Today, Product Lifecycle Management is used in almost every industry.

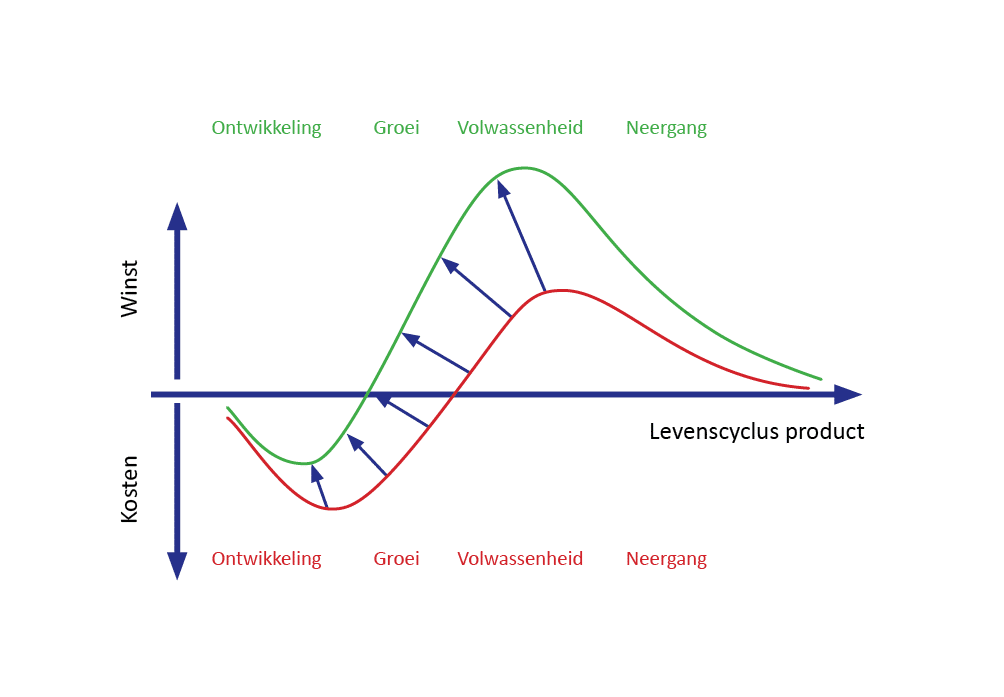

Every product on the market goes through four distinct phases: development, growth, maturity and decline. These phases are described by the “Product Life Cycle” (PLC). The duration of each phase can range from a few weeks to many decades. Not all products go through all phases because some products never reach the market. However, any product that reaches the market will at some point disappear again (decline).

The intended result is that the red line in the figure above moves up to the green line, so that a higher yield is obtained. Earlier market introduction of a new product or service and faster growth to the maturity level will increase competitiveness and profitability. To achieve this, organizations must have a good understanding of the market, competitors and technology.

PLM systems help organizations better manage increasing complexity and technical challenges. PLM systems include all available information about developments, market, techniques, processes and one’s organization. In this way, PLM systems support the management process of a product or service in each of the four life phases, forming the backbone for companies. Since the goal is to minimize risk of disruption during product launch, PLM works closely with Design for Six Sigma.