Eliminating waste

Lean distinguishes three types of variations. The elimination of variation and waste is a key tenet within Lean.

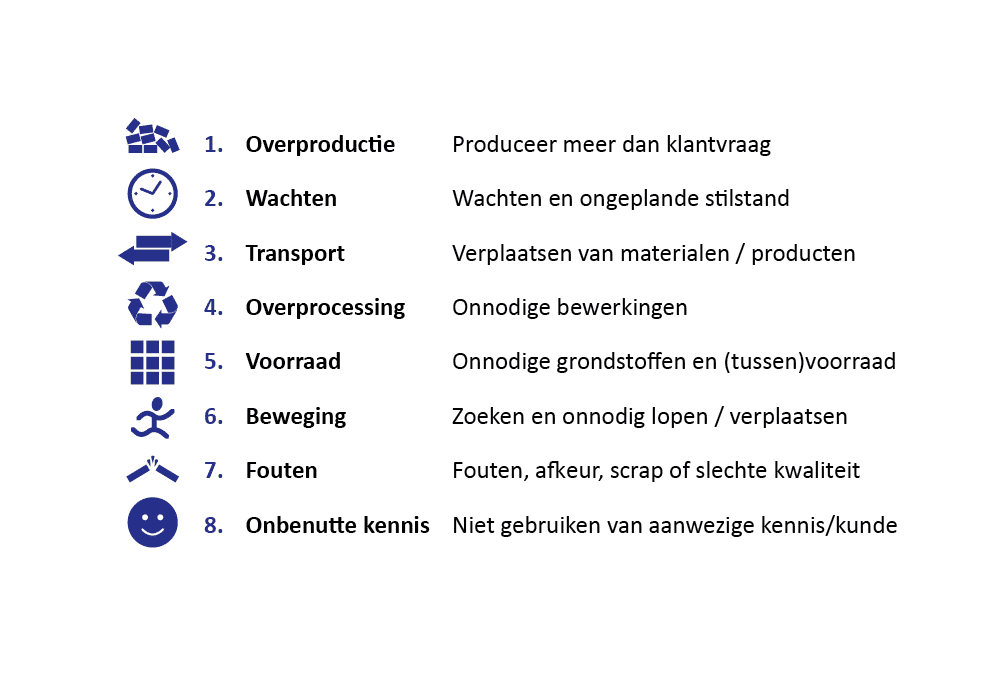

- Muda (Waste, uselessness, non-value adding, not suddenly good)

- Muri (Overload, impossibility, beyond one’s control or expertise)

- Mura (Unevenness, irregularity or lack of uniformity).

In most Lean programs, Muda is the first M to be picked up because it is easier to identify than the other two. Reducing Muda can be achieved by eliminating activities that do not add value. Any activity in a process can be classified as:

- Value Adding / Value Adding (VA) Customer is willing to pay for this.

- Non-Value Adding / Non-Value Adding (NVA) Customer is not willing to pay for this.

- Necessary Necessary for the process.

A Value Adding activity must meet the following requirements: the customer is willing to pay for the activity, it must be done correctly the first time (First Time Right) and the action must change the product or service in some way. If any of these criteria are not met, the activity is classified as a Non-Value Adding and therefore wasted or “Muda.