DMN-WESTINGHOUSE: How to work smarter, that’s what it’s all about!

Johan Meima joined DMN-WESTINGHOUSE in 2011 as Quality manager. A great challenge lay ahead. DMN-WESTINGHOUSE was an old-school production company with a focus on manufacturing. Which is fine, of course, but what an outsider especially noticed is that it looked rather gloomy inside. Nowadays, even in production it is clean and light, pleasant to work. “So we started with that. A big cleanup,” Johan said.

DMN-WESTINGHOUSE has been developing and manufacturing metering sluices, diverter valves and other, related components for the bulk material industry for over 40 years. DMN-WESTINGHOUSE provides custom components for the food, dairy, plastic, (petro) chemical, pharmaceutical, mineral, energy and biomass industries worldwide. Since its founding in 1950, DMN-WESTINGHOUSE has been a manufacturing company. Today, metering valves and diverter valves are machined and assembled in in-house production plants in the Netherlands, USA and Germany. The highly qualified staff and highly advanced machinery enables DMN-WESTINGHOUSE to manufacture high quality components with detailed finishes and precise clearances.

“How to work smarter is what it’s all about!”

Johan: “Our process is divided into three ‘Gates.’ ‘Gate 1’ means the moment of (telephone) receipt of the order up to the confirmation and issuing of delivery time. ‘Gate 2’ is bringing the various product parts together for assembly. So the procurement of materials and in-house production. Finally, “Gate 3” is assembling the product. All materials are provided. The product is assembled and prepared for shipment.

Being the first to understand your processes

First, we addressed Gate 1 through Value Stream Mapping. We went from 16 days lead time to 2-3 days lead time. And in our latest approach, we even go to 0 days by being able to issue a delivery time to the customer almost immediately, when the order is placed.

In Gate 2, we are now at 11 days. The next step is to improve “flow. That is, we want the various parts to flow smoothly through the process, without stagnations, intermediate stocks or just shortages, and precisely matching customer demand. We will address this process in early 2017, with the goal of further reducing lead times.

The improvement process on Gate 3 lead times is ongoing. We are now in a remodel. The process now takes about 4 days. However, we will first continue to refurbish and redesign the production environment. This does not directly benefit financially, but it does provide a better and more organized workplace. Then we will look at how to work smarter.

58 Improvement ideas after Yellow Belt training for everyone

In late 2014, discussion arose as to whether improving using the Lean philosophy and principles was the right way to go. Therefore, with the staff and management, we visited Scania in 2015. That was the deciding factor in moving forward. We asked Symbol to provide Yellow Belt training to everyone from the telephone operator to the management, so that we all speak the same language and can participate and think along. We then invited employees to submit their improvement ideas. From this, 58 suggestions immediately emerged in the course, for example, digitizing the archive, rearranging the sales department, rearranging the sawing department, introducing new warehouse shelving with a clear inventory management system, simplifying the product and introducing handheld scanners. The goal is to tackle up to 5 projects at a time and also a number of “micro-projects,” small projects that can achieve quick results.

Making changes takes a long time

We certainly faced resistance. Change is a difficult journey. We deal with this by making issues negotiable, educating people. It is very important to involve everyone. And to have support from management. But sometimes you just have to do it anyway. Taking steps so that being right and being right can come together. But it is a long journey, in which tenacity and perseverance are necessary qualities. In our case, it is expected to take about 7 years. Now it is safe to say that continuous improvement is in everyone’s mind and we want it to stick.

We have experienced growth. Everyone must begin to see that there are plenty of opportunities for improvement and that it will pay off. The role of Symbol’s trainer was very important here. The trainings and also outside of them involved working with colleagues with whom there was never contact before. This was found to be very inspiring. Ultimately, one wants to see that all the efforts and changes pay off.

In the Yellow Belt training courses, project teams were established, composed of engaged employees. The Yellow Belt is a broad training, from which people at least take a lot of ideas. Everyone gets a chance to bring these ideas to fruition in project teams as well. Team collaboration is hopefully permanent. You also have to give people a chance to experience change.

Internally, we now have two Green Belts and two Black Belts. Allocating time for their improvement projects is difficult. By making time for it, we also hope to release creativity. As of July 1, have someone in a position that may devote 40% of their time to Lean Six Sigma improvement projects. That’s another step!

The whole transformation certainly affected the atmosphere. The spaces are cleaner and brighter. People see that something is happening. This is not to say that people always agree that this is to the credit of the new “Lean” thinking.

Creating awareness

What I would have done differently now? I got started too easily, without really bringing or getting the management on board. Their active role is critical in the success or failure of a Lean implementation. Last month, we still organized a session with management to talk about this. Management must be visible, in front of people. No one mentioned customer focus, showing leadership, conditions, etc. Since we did the master class with management, this awareness is there. Management really has an important role in this. In doing so, we had no sense of urgency. We didn’t choose those either. So whether we made changes or not, there would be no immediate blood out. ‘Falling behind in the market’ was mentioned here. But people should feel the same way. The market is indeed changing. Customers are suddenly very large. And you increasingly have to deal with regulations from Europe. Now we are cautiously leading the way in our industry. We are able to link up well, not least because we have a seat in the working group at FME that also discusses European laws and regulations.

Tips for other organizations? Create a sense of urgency. For example, read the book “Our Iceberg Melts” by John Kotter. That’s a great start to creating awareness. And, as mentioned, board and management on the front lines is a prerequisite for success. They need to speak out clearly on topics such as “what is true customer satisfaction? Is that your own wallet or is it what the customer demands? Then you have to translate this into your process, translate it smartly. Involve the entire organization and train people!

We are proud that our people are picking it up so well now. I have a lot of confidence in it. In engineering, people also want to advance. Every night I wonder expectantly what will improve tomorrow. I like to inspire people to improve and but also that in doing so they can be themselves in their work. Improve in their team, as an organization, as well as in their own processes. How to work smarter. That’s what it’s all about!”

Johan Meima met Dick Theisens, CEO of Symbol BV, at a meeting of LSSN (Lean Six Sigma Netherlands). The fact that Symbol offers thorough training and examinations according to LSSA guidelines in addition to consultancy and coaching, which results in an internationally recognized diploma, was an important motivation to choose Symbol.

Latest news/blogs

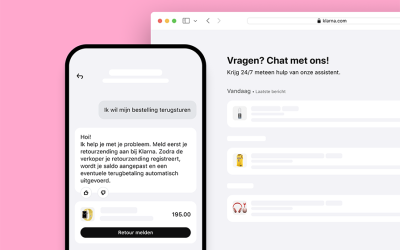

Klarna saved 40 million with AI but lost the trust of its customers

Klarna saved40million with AI but lost the trust of its customersThe question sounds absurd: how...

How do you eat an elephant?

Dutch productivity is falling again - and that offers precisely opportunitiesLabor productivity in...

From Theory to Practice: Junior Consultant at Stoneridge

From theory to practice: Junior Consultant at Stoneridge Before working at Symbol, Junior...