Enthone: Safety awareness should be “daily business”

After two incidents involving the release of hazardous materials, PBZO company Enthone in Den Bosch was placed under increased government supervision. Enthone would not be “in control” and had to come up with a plan of action within a month. Symbol went there to work on the “Time for Safety” safety awareness plan, part of the plan of action.

“Safety awareness should be daily business”

Time for safety

Enthone, subsidiary of the Alent Group, is a world-renowned supplier of chemicals for the electroplating industry. We spoke with Manno Hellemons, Operations Manager, Ad Kersten, KAM Manager and Werner Cornelissen, Manager of Financial Systems Europe and closely involved until August in his role as Financial Director of the plant and currently still chairman of the steering committee that coordinates and monitors the projects. The name of the project is “Time for Safety. “We made a conscious decision to do that,” Werner said. ” We want people to think about it when they see an unsafe situation and report it.”

Recognizing each other’s competencies

“The plan of action consisted of five main pillars,” Manno says: “The first pillar stood for identifying and evaluating risks. The second pillar was improving technical facilities. Competence development of employees is the third pillar. The fourth is creating safety awareness among employees. Finally, the fifth pillar concerns communication with the environment. Particularly for the employee safety awareness part, we enlisted the expertise and knowledge of Symbol, then FirmXperts.” Ad: “In management and middle management, Symbol started working with analyses, from which the DISC profiles emerged. With the help of this methodology, we got a clear picture of what personalities people have and, perhaps more importantly, how we can best interact with each other while making optimal use of everyone’s strengths.”

Disc Model

Quick wins in the workplace

When this first part was completed, all 80 employees were assigned to working groups consisting of four to five people from different disciplines in the organization. The goal of the groups was for employees themselves to take a conscious look at safety by looking for situations that could be improved. Any improvement under 1000 Euro could be implemented immediately after a brief presentation without further approval. As a result, engagement was optimal and results were quickly visible, called “Quick Wins. Ad: “I found the cooperation and commitment in the teams that started working on the projects the most surprising thing in the whole process. By looking with different eyes, especially with colleagues from outside production, we have greatly reduced a jumble of safety information signs and pictograms resulting in a clear space.”

Quick Wins on the shop floor have resulted in an uncluttered space.

Make it daily business

Tips for other companies? Werner begins, “Listen carefully to the staff, what they see as areas for improvement. They need to sense whether they are in a safe or unsafe situation.” Manno continues: “And make sure you have visual effects so that people see results pretty quickly. So make sure you have quick wins. “By the way, 5S is also an important point,” says Ad. “We’ve been doing 5S for years. Because keeping your work environment tidy contributes tremendously to safety.” Now it’s about ensuring continuity.

It may not stop. It must remain part of normal business operations and business strategy. “We’ve had 20 little projects now,” says Werner: “We have to keep making sure people stay actively engaged, not just through training, but hands-on tackling a problem. To keep them aware. It has to remain daily business.”

Latest news/blogs

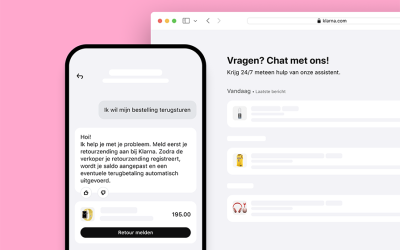

Klarna saved 40 million with AI but lost the trust of its customers

Klarna saved40million with AI but lost the trust of its customersThe question sounds absurd: how...

How do you eat an elephant?

Dutch productivity is falling again - and that offers precisely opportunitiesLabor productivity in...

From Theory to Practice: Junior Consultant at Stoneridge

From theory to practice: Junior Consultant at Stoneridge Before working at Symbol, Junior...