10 steps to develop your organization into

‘Digital Champion’

It has been 12 years since the term Industry 4.0 was introduced. This was at the Hannover Messe in 2011, when Professor Wolfgang Wahlster, director and CEO of the German artificial intelligence research center, addressed the audience at the opening ceremony. He urged companies to be ready for the next industrial revolution. When we look – now 12 years later – at where we are, it is still sad for most companies. In this blog, we look at the current situation and name 10 steps that will help in digital transformation.

Back in the early 2000s, the German government recognized that a new approach within the industry was needed to remain competitive in the global marketplace. In 2013, the German government launched a program called “Industry 4.0,” which aimed to promote the digitization of production processes and the integration of new technologies.

Status of Industry 4.0

Industry 4.0 is often mentioned in the same breath as robotization, digital transformation, Internet of Things, big data and artificial intelligence. Many of these concepts are still far removed from the daily reality of an average company. Even if the terms are understood, their application is often far from it.

As mentioned, we are now a decade into our journey and the question is what is the status of Industry 4.0. Indeed, some articles still state that we are at the beginning of this revolution. And that is still the case for the vast majority of companies. Over the past decade, there has been a lot of talk about Industry 4.0, but few have taken steps that can be characterized as a “revolution. They are often small steps such as implementing certain software tools or sub-optimizing processes.

An industry revolution is characterized by an upheaval initiated by a technical innovation accompanied by large-scale organizational and social changes. According to this definition, this is not the case when a new machine is purchased or a single software tool is installed. It’s really about a completely different way of producing.

Lagging behind in digital transformation

By the way, not only in the Netherlands but throughout Europe we are far behind developments in America and Asia. Only 5% of European companies can be classified as Digital Champions (PWC, 2018). Over a third of Asian companies and a quarter of U.S. companies have plans to develop mature digital ecosystems, compared with only 15% in Europe. We all know the big digital platforms in America such as Microsoft, Alphabet (Google), Apple, Meta and Amazon, and the biggest digital players in Asia such as Alibaba, Tencent, TSMC, Mitsubishi, Canon and Nintendo. The Forbes top 100 digital companies include only 16 European companies, with the Netherlands represented by Philips, ASML and NXP.

In addition to these tech giants, inspiring examples can also be found within normal companies. Consider 247TailorSteel, which will build its sixth plant of the future this year, or a chemical company in Rotterdam where the production volume of chlor-alkali is automatically adjusted according to the availability of green energy. Consider also Jungheinrich building a fully automated logistics center for the Dutch company Prodrive Technologies, or a water treatment plant that can run completely unmanned outside business hours. An example of product innovation is the company Deron in Gendt, Gelderland, which developed a Smart mattress for healthcare that incorporates sensors that transmit information about patients’ sleep status and minimizes false alarms.

A roadmap to becoming a Digital Champion

The thesis is that every organization must work on product innovation and digital transformation to ensure that the organization is future-proof. If an organization does not pay enough attention to this, at some point a party will emerge that will dominate the market. Think about what happened with the DVD or booking offices for vacations. The following are 10 steps to guide digital transformation. It is not the intention to initiate all the steps at the same time, but it is important to put some of them on the strategic agenda.

1. Digital strategy

Develop a roadmap to make products and services increasingly digital, or offer them online (globally). Look at where services can be added to the existing product portfolio(servitization).

2. Competence

The digital transformation of an organization requires new competencies in managers and employees. Many have a huge gap in knowledge, which is also changing at a rapid pace. Ensure that the appropriate knowledge and expertise is present within the organization through training and through recruitment.

3. Standardization and flexibility

Develop products and services based on standardized building blocks that fit together seamlessly (modularization). Realize well that standardization and flexibility are not a contradiction. Ensure that machines and employees can switch seamlessly from one product to another(Agile).

4. Simplification

Map processes and appoint process owners. Eliminate waste(Lean) and focus on simplifying processes as much as possible. Place ownership as low as possible in the organization and minimize management and authorizations.

5. Automation

Map transfer moments. These are process steps where data is transferred from one system to another. Automate these transfer moments using APIs or RPA (Robotic Process Automation).

6. Flawless production

Map process steps where human interaction with the product occurs. Minimize the chance of human error by developing Poka Yoke solutions for activities that cannot (yet) be automated.

7. Logistics process performance

Measure logistics performance such as start and end times for key process steps.

Make these visible in performance dashboards such as PowerBI.

8. Qualitative performance

Ensure that critical characteristics for each product are measured throughout the process. These are characteristics of the product that are important for good product performance and customer satisfaction. Make these characteristics visible in performance dashboards and use real-time SPC tools.

9. Continuous improvement

Develop a process of continuous improvement, looking daily at product and process performance that does not meet requirements. Make data easily accessible for analysis by Green and Black Belts. Apply techniques such as Process Mining and Data science to analyze and improve performance.

10. Rethinking

The digital transformation of an existing organization can get bogged down by technical roadblocks and objections from employees or customers. Therefore, ask yourself the following question, “What would the factory and organization look like if we didn’t have to take anything or anyone into account, and we could develop everything from scratch?”

This will undoubtedly lead to new insights.

Implementation of Industry 4.0

Like any transformation, digital transformation is not easy. Most managers and employees see problems rather than opportunities. On top of that, the techniques and tools necessary for digital transformation are changing very quickly. But inaction is not an option. In any case, make sure you are informed of developments. Attend events and sign up for training, or organize an inspiration session with the entire MT on the possibilities of Industry 4.0. On September 28, Symbol, together with its partners, is organizing an event on Digital Transformation. More info can be found at https://www.symbol.nl/event-digital-transformation. Also, our consultants can help your organization go through the above 10 steps on digital transformation. Take the first step today and contact us for a free consultation.

Also interesting to read

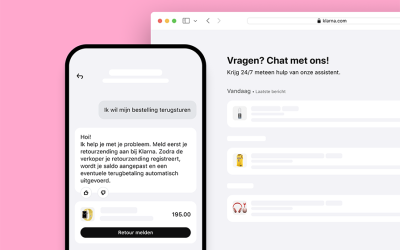

Klarna saved 40 million with AI but lost the trust of its customers

Klarna saved40million with AI but lost the trust of its customersThe question sounds absurd: how do you eat an elephant? But the answer is surprisingly simple and powerful: one step at a time. This metaphor is often used to describe how to tackle large, overwhelming...

How do you eat an elephant?

Dutch productivity is falling again - and that offers precisely opportunitiesLabor productivity in the Netherlands fell again in 2024, CBS figures show. While the economy is growing, the output per hour worked is actually decreasing. A signal that traditional ways of...

From Theory to Practice: Junior Consultant at Stoneridge

From theory to practice: Junior Consultant at Stoneridge Before working at Symbol, Junior Consultant Wisse Bos had never heard of a Production Part Approval Process (PPAP). Now he knows all the terms associated with a PPAP - such as PSW and PCN - like the back of his...