DMADV

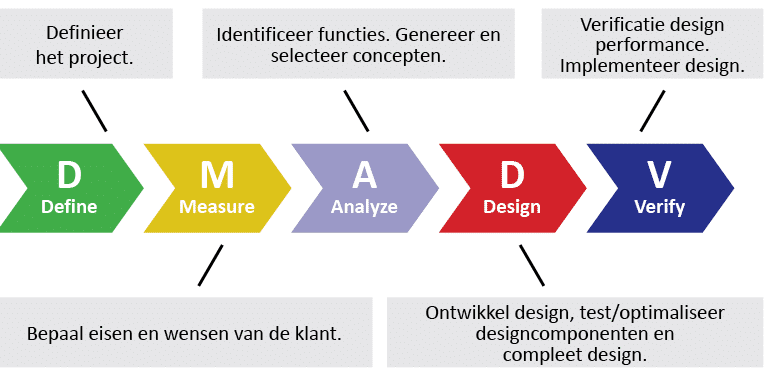

Design for Six Sigma follows a different roadmap than the regular Six Sigma DMAIC roadmap. A commonly used roadmap is the DMADV roadmap, which stands for Define, Measure, Analyze, Design and Verify. While the DMAIC is applied in breakthrough projects to solve existing problems (CIMM levels III and IV), the DMADV is applied in innovation projects to prevent problems.

Similarities between DMAIC and DMADV

There are a number of similarities between the DMAIC and DMADV roadmaps. They are both data-driven approaches, both use similar techniques and both are used to minimize defects. To achieve this, both roadmaps use the same tools and techniques, such as the MSA, hypothesis testing, DOE, etc. Therefore, all tools and techniques used within Six Sigma can also be used within Design for Sigma.

Define:

The Define phase is similar to the DMAIC Define phase. Most DMADV projects begin with a risk or specification that is new to the organization or difficult to meet. The purpose of a DAMDV project is to investigate this risk and define solutions to it. If the solution to the risk is already known, there is no need to start a DAMDV project.

Like DMAIC projects, the Champion will assemble a project team and appoint the project manager. During the Define phase, a Project Charter will be prepared that includes the problem statement (risk), objectives, scope and schedule. All of this must be consistent with the overarching project, the Voice of the Customer and the Voice of the Business.

The Define phase should also provide an estimate of the financial implications, coupled with the risks. Hard substantiation is often not possible here because the probability of the risk actually occurring is not known. Therefore, an estimate by the team and the Champion is sufficient to justify the time, resources and budget to start the project. In some cases, missing the business is taken as a starting point.

Measure:

Within the Measure phase, the customer’s risk or requirement is made concrete and specific. The specific measures are called critical characteristics or “Critical to Quality” (CTQ). CTQs describe what is important for the quality of the process to meet customer specifications. Each DAMDV project focuses on a limited number of external CTQs that reflect a risk or customer specification. It is necessary, as in DMAIC projects, to define the requirements for internal CTQs and how they should be measured. The team must ensure that the measurement system is adequate by conducting a measurement system analysis (MSA).

This can be difficult because in a development project there is no prototype to perform measurements on. In this case, a Monte Carlo simulation can be used to analyze the sensitivity of a prototype system and predict the yield and/or Cp and Cpk values. The Monte Carlo method is a predictive technique based on generating a large number of samples, sometimes theoretical. A detailed treatment of Monte Carlo simulation is beyond the scope of this book.

Analyze:

To achieve a certain value for the critical characteristics or CTQ, it is necessary to identify the factors that affect the performance of the CTQ. The purpose of the Analyze phase is to identify, validate and capture these influencing factors (x1..n) that are important for a stable and capable CTQ of Y.

There are several methods for identifying potential influence factors. In general, the same techniques can be used as in the Analyze phase of the DMAIC, such as regression analysis and Design of Experiments (DOE). Possible influence factors are examined to determine the transfer function, which is a mathematical representation of the relationship between the influence factors (X1..n) on the CTQ or Y.

Design:

Once the transfer function is determined, the values of the influence factors can be determined to arrive at an optimal and robust design. To determine the optimal settings, Response Surface Modeling is often used in addition to Design of Experiments. In some DfSS projects, the reliability of products and machinery is important. Reliability engineering or “Reliability Centered Maintenance” (RCM) is often used in such projects. This is a specific and very broad field. These techniques are beyond the scope of this book.

Within the Design phase, the first prototypes are produced or assembled. This is also often the first time a product is actually available to perform measurements on. At the end of the Design phase, a release plan or test plan is created, which is used in production to monitor products. This phase also includes updating the Process FMEA and Control plan and creating work instructions.

Verify:

Once the first prototypes are produced, there are two more steps to go. First, the design must be validated. It must be ensured that CTQs meet customer specifications to ensure that the process is capable. For this purpose, samples are drawn from the first production batches and a capability analysis is done. Often additional requirements are imposed on the first production batches or additional reliability tests are performed. These are called “Launch controls. The final step in a DAMDV project is to update documents and procedures and then neatly close the project. The party can now be celebrated.

Like the DMAIC roadmap, the DMADV roadmap consists of about 14 steps. There are several variants for the DMADV roadmap.

| Define | 1. Define project and establish delineation |

| 2. Define functional requirements. | |

| 3. Plan and document the project | |

| Measure | 4. Translate functional requirements into technical requirements Y |

| 5. Set objectives for requirements | |

| 6. Evaluate the measurement system | |

| Analyze | 7. Develop concepts / Concept selection. |

| 8. Determine factors of influence (X1..n). | |

| 9. Determine Y = f(Xi) | |

| Design | 10. Determine the optimal design |

| 11. Develop a prototype | |

| 12. Design a release plan/testing plan | |

| Verify | 13. Validate the design |

| 14. Close the project |

Become an expert yourself?

Do you want to (further) develop yourself in improvement strategies? Then check out our Lean and Lean Six Sigma training courses. For example:

► Lean Green Belt

► Lean Black Belt

► Lean Six Sigma Green Belt

► Lean Six Sigma Black Belt