First improvements Yellow Belts at CSK visible!

At our relationship CSK, which specializes in manufacturing dairy products, seven groups have now been trained to become Lean Six Sigma Yellow Belts as part of the “culture to grow” project. The first improvements are visible. For inspiration, CSK shared some great examples with us.

1. A smart directory system makes finding easy

Folders are found and put back in the right place at lightning speed due to the diagonal tape. A missing folder is also immediately noticeable this way.

2. A tidy and orderly microlab.

In the QC micro lab, a much better overview was created and more space and tranquility created by improving and optimizing the layout.

3. Prevent dumping of stuff

The unnecessarily large table in hall has been replaced. This gives more space in the hall. Moreover, no more stuff is “dumped.

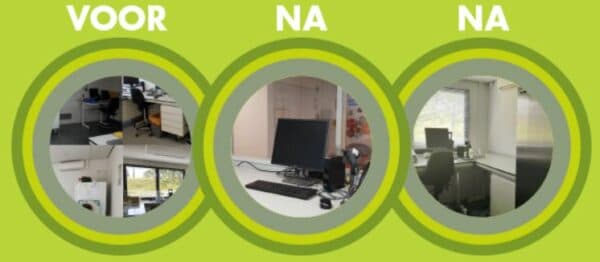

4. More workspace available

By making better use of cabinet space and eliminating unnecessary items, less cabinet space is needed and more workspace is available.

It is great to see the training and improvements leading to immediate results. We wish CSK every success with continued improvements and in further implementing a culture of continuous improvement!